The 8 P’s

Hey, I’m still here! It’s just hot out and time is limited in the summer. It’s hard to eat too many munchkin’s when it’s 90 degrees and 90% humidity.

Things are moving and grooving over here though! Today we’ll review the 8 P’s:

Patents

Ping Pong

Prototypes

Production

Poutine

Pontoon Boat

Pals

Path Forwards

Patents!

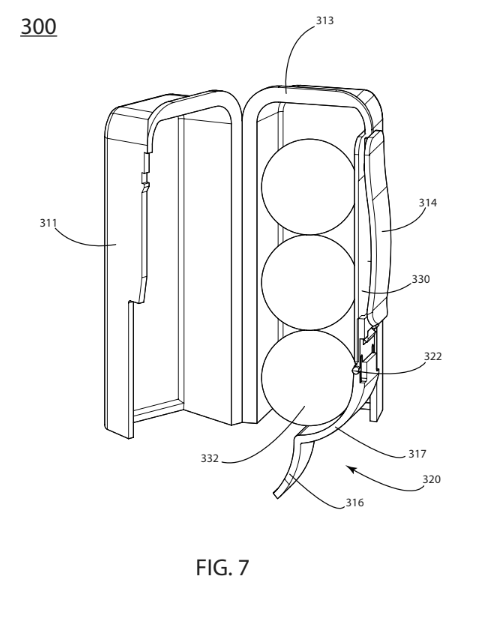

I’m happy to announce that the provisional and design patent for the Donut Hole-der is now pending. I have one year to make changes and revise the design before I need to lock things down. This is a crucial first step in ensuring nobody runs away with my idea and makes it on their own. I worked with the team at Keeley DeAngelo to craft the patent and create the images for the filing. I’ve been listed as an inventor on 10 or so patents before, but this one felt extra special since it was my idea (and my money 🙃).

It’s a beauty, isn’t it? The patent includes some really interesting things here as well. The dropstopper is featured heavily, since it prevents the items above from falling out while simultaneously providing the spring force for the dispenser.

The patent covers the plastic enclosure design, as well as alternative concepts that could work with retail friendly concepts like a paper tray or cardboard tube. Imagine a world where you can buy your donut holes in a pre-filled cannister!

Another thing that I’m jazzed about is how the scope of the invention has been broadened from just donuts to other items.

”The present disclosure relates generally to the field of mechanical dispensers. More specifically, it pertains to a portable, manually-operated dispenser for serially dispensing individual items from a stack of such items, particularly confections, balls, pills, or other uniformly shaped objects.”

Balls, pills, and other uniformly shaped objects is where things can get really fun. Think: tater tots, chicken nuggets, or even…

Ping Pong Balls!

Yup! They fit almost perfectly. At 40mm in diameter and weighing very little, they’re a perfect item to be dispensed here. A few tweaks will be required to get them to dispense more reliably but I think I can design it in such a way that it won’t impact your day to day donut hole experience (aka your D2DDHE). According to an incredibly brief Google search, this would expand my market base by a good amount.

Golf balls could also work, but the additional weight may pose a challenge. Stay tuned here! Sounds like I need to make more….

Prototypes!

Up until now, I’ve been cranking out prototypes on my handy dandy 3D printers at home. I have three Bambu labs printers I use nearly every day and love them (not sponsored, but happy to discuss it!). I was able to find 3D printing filament that closely matches the brand colors for Dunkin, which also helps to visualize the final design easily. These 3D printers are great for quick and robust prototypes, but aren’t as good for creating parts that represent the final design. For that, we’ll have to get fancier.

There are tons of ways to create prototypes (and I’ve written a lot about it here), but I’m going to be pursuing three main approaches for higher end units: hand painted SLA 3D prints, urethane cast units, and SLS 3D printed units.

Hand painted SLA parts can be made domestically and quickly, and it’s an excellent way to create “props” for marketing content like photos and videos. They are super detailed but tend to be a bit more fragile, and the paint can wear off over time. Here’s an SLA print before the paint is applied:

Urethane cast parts are more expensive and require custom molds, so they take more time to create. They can accurately match the final color and texture of molded plastic parts, which makes them a great candidate for beta testing units. I’ll have more details on this process - and some great pictures - soon!

Lastly, SLS prints are robust and still a far higher detail than my at home printers. They help me understand how the parts fit together and will react to drops and use.

Using a variety of prototyping methods is a great way to validate all aspects of a design before investing more money in….

Production!

The end goal here is to injection mold these units for mass production. In the real world, I design parts for this manufacturing process all the live-long day. This process is how most plastic parts are made. It’s inexpensive, repeatable, and allows for super high fidelity parts with a variety of materials, colors and textures.

Designing parts for injection molding is all about knowing the rules and also how to break the rules. There are many many many excellent guides for those curious to learn the basics. Learning to break the rules comes with experience and great mentors, and I have been very lucky to have both.

The body of the Donut Hole-der is one of the more complex parts I’ve ever designed, since it requires so many components to come together and form the mold. For reference, a simple part would have two parts that come together to form a mold. This part has 6.

Fun, right!?

Over the last 7 years, we’ve also created excellent partnerships with manufacturing partners domestically and overseas. I’ve already sent the files to a few of them for quotes and have been extremely happy with the numbers I have seen so far. Even if we don’t get a major brand to commit to working with us, I am confident I can mass produce these units at an affordable price. More on that later 😎. All this talk of engineering makes me hungry for some….

Poutine!

Goddamn, what a food! For those of you who don’t know, poutine is made of French Fries covered in gravy and cheese curds. It’s a delicious Canadian delicacy. Just like Tim Hortons!

That’s right, the offer is officially on the table. I’m willing to accept Canadian citizenship in exchange for the rights to the hole-der. I think it’s a great deal.

Of course, my offer still stands to exchange the rights for a…

Pontoon Boat!

I recently had the privilege of voyaging on a Bennington Pontoon boat. It’s a lovely watercraft, but too fancy for my blood. I also looked at the SeaDoo Switch boats, which seem like the next evolution in pontoon boating. They also have a third pontoon so people call them “tri-toons” and I really like that. I really really like that. Here’s a donut boat:

Honestly, I’d be happy to take any pontoon boat as long as there’s enough room for my…

Pals!

I couldn’t have come this far without the support of some amazing folks, and I’m super grateful to have them in my orbit. In no particular order, I’m thrilled to thank the following people:

Andrew Brase is a wickedly talented Industrial Designer. He gets all the credit for the paper tray concept and for refining my design into something that looks excellent.

Lindsey Gideon is our Chief Marketing Officer at informal and has been helping organize interviews, editing my writing, brainstorming on strategy, and helping improve the site.

Nate Padgett, my co-founder at informal, has been immensely supportive of this weird project as a way for me to better learn the rest of the ‘biz. He’ll be heading up go to market strategy as this project progresses, and I cannot wait.

Nicole Eaton has been my fixer, connecting me to folks who are eager to help and spread the good word. She’s brought a unit to a Dunkin’ already for feedback and has some crazy leads we’re hoping to pursue. I can’t wait to share more.

Gustavo Fontana has been our prototyping development partner. He and his company, Fresco Designs, have been instrumental in helping create higher fidelity prototypes for marketing and testing.

Luke Plummer, a local Mechanical Engineer and friend, has been helping me get higher quality SLS parts for evaluation, as well as providing an extra set of eyes on my design and my sanity.

Jackson Seidenberg, another amazing Industrial Designer and friend, created the incredibly powerful Dear Dunkin’ song. It actually is really great and I listen to it more than I’d like to admit.

Chris Rill, who calls many of my ideas stupid but seems to like this one a lot and might have given me the best pitch EVER for Dunkin’. It’s so good that they would be crazy to turn it down. I’m actively pitching it now and I don’t want to ruin the surprise yet.

My brother, Wes Holland, who helped me crack the code on the drop-stopper. His brain is truly second to none and you should buy his amazing hand made bike bags.

My wife, for putting up with what most would diagnose as a somewhat early midlife crisis. For listening to me ramble about munchkin geometry, for consuming reckless amounts of donuts with me, for falling asleep to the buzzing of 3D printers, and for the endless support.

All of my friends and family who I have subjected to this project so far. From sending them the website as beta testers, to making them try the device at parties, to helping brainstorm pitches and concepts. You rock.

I have been overwhelmed by the support of friends, family, and strangers on LinkedIn for this project. It’s been so freaking fun to spend time on something that makes people smile.

Path Forwards!

This update was a doozy, thanks for either:

- reading the whole thing

- skimming it and realizing you’re almost at the end, then starting to pay attention again. Or

- scrolling all the way down, and then up a little bit

However you got here, I appreciate you.

I still have some irons in the fire for getting this to the people that need to see it at Dunkin’.

I think it’s a great deal.

I’m more than happy to do this all over with Tim Hortons. And, yes, I do own the domain www.heyhortons.com 🍁

I’m more than ready to do this on my own if needed. I have the quotes and the support to make it happen. It’s just more fun if I can partner with someone. Please, please, please share this with people so I can get the word out there.

One way or another, it’s gonna happen.

💗 Sam