Let’s talk $$$

Hi hello and happy 2026! (?)

Things are happening! I’ve been shipping out a few 3D printed beta units to testers, and I thank you all for trusting me with your mailing address.

I promise I mailed out more than 4. I have many more though! Want one? Smash the button below:

Manufacturing Quotes:

Now that I feel pretty damn good about the state of the design, I’m starting to get some quotes on how much it will cost to mass produce these bad larries. As a reminder, I have a real job and I actually design parts for injection molding all the live long day. This is what I’m pretty good at!

Before we get into that, let’s do a quick overview on Injection Molding. I think it’s fascinating and its used to make pretty much everything around you, so I hope you find it fascinating too!

Buckle up, this is a long ass one.

What is Injection Molding all About?

That’s a great question!

Injection Molding is (probably) the most common manufacturing method out there. Molds are machined out into shapes using very precise and expensive machinery. These molds close together, leaving hollow cavities between them. Plastic pellets are melted and injected into this cavity, where they cool and solidify into hard plastic parts. The molds open, the part is ejected, and the process repeats.

Image source: https://makeagif.com/user/Rhobar_IncPlastic Injection Molding rocks for a few reasons:

First, it’s highly repeatable. Parts are nearly identical between batches, and over time. LEGO parts are made using this process and their tolerances are pretty insane.

Second, it allows for high detail and textures. You add the texture to the mold, which is picked up on the surface of the plastic. This allows for some super interesting textures and patterns, from simple matte textures to faux leather. My favorite is the tiny little shapes molded into the PS5 controller.

Third, it’s pretty inexpensive. The cost to machine the metal are the main driver of pricing and depend greatly on the complexity of the design. Expect to pay anywhere from a few thousand dollars to many tens of thousands of dollars. The cool part, though, is that the cost per piece manufactured is super low. We’re talking pennies at mass production scale. This means your effective cost per part is still very cheap once you’re making thousands of them.

A quote for molding will include the tooling cost as well as costs at various quantities. Expect to pay far less per unit at 250,000 pieces than at 250!

One thing to note about Injection Molding is that it takes a while! Expect 6-8 weeks to pass from paying for the mold and reviewing first parts. From there, expect another 2 weeks to dial everything in until it’s ready. That’s 2+ months.

Yes, you can take shortcuts. No, I don’t recommend it :)

Why not 3D print them?

This isn’t a great fit for 3D printing long term, and very few products really are!

The economies of scale for 3D printing never reach the low low costs of Injection Molding. Plus, many 3D printing materials are not food safe and tend to be more fragile than molded plastic parts. It’s also hard to reproduce the textures and colors I want here which help make this look and feel so good.

3D printing is an excellent option for making a small amount of parts, or when the design varies from part to part. Aside from that, it’s hard to justify printing at scale. I’ve tried it, I’ve quoted it, I own many 3D printers and have designed the machines in the past. I don’t recommend it.

The contenders:

Now, typically I would send this off to one of my trusted vendors in China and proceed with manufacturing. I know them, trust them, and the price and quality are incredible. However, this is a really rad opportunity to do an apples to apples comparison of domestic versus overseas manufacturing. We hear about it (a lot) these days, and I have many many quotes to show the price difference. However, these quotes aren’t something I can just share with the world. Until Now!

So, let’s look at the actual costs to make something like this and compare it with a few options. We’ll be looking at four vendors:

🏭 Vendor 1: A Chinese Injection Molding Company

I love these guys, and use them on anything that just needs plastics. They’re a smaller facility that specializes in the creation of the molding tools and manufacturing plastic parts. We used them with Burrito Pop and a handful of other clients and the cost to quality ratio is amazing.

🛠️ Vendor 2: A Chinese Contract Manufacturer

I also love these guys, and they’re my go-to when we make more complex things with electronics in them. They contract out their injection molding to a partner facility and charge a markup on their rates. As a result, I expect them to be more expensive but maybe offer another layer of Quality Control on top.

🦅 Vendor 3: A US Based Injection Molding Shop

Someone from this company reached out to me on LinkedIn and I think they’re great! Their tools are made in China and shipped across the ocean to their facility in the US, where they do the manufacturing. I expect costs to be higher across the board compared to vendor 1 + 2 since labor costs are much higher here and we’re dealing with shipping and logistics.

🌐 Vendor 4: A Rapid Injection Machining Shop

I have strong feelings about these types of companies, and my recommendation is to typically avoid any vendor who appears on the first page of a google search. These vendors are great at making so-so quality parts within a matter of weeks, and offer instant quotes online. In the world of hardware, you’re usually using these vendors only if you’re already in a really shitty situation and need parts super fast or you’re ignorant to the fact that better options exist.

Why not quote outside of China?

In short: laziness and confidence. Getting quotes with new companies takes time and effort and I’m putting a lot of both into this already. Also, most of the tooling comes from China already. They’re the experts at mass manufacturing, and they’re inexpensive.

I trust my vendors with my Intellectual Property and am not worried about copy cats with them. Folks get really spooked about this, but it’s just like any relationship. Referrals and past experiences are key. You build trust and hope the other party wants you to grow and become a major source of revenue for them too. I recommend visiting these factories if you can. They’re so cool.

I also won’t let the chaos around tariffs change my long term strategy yet. I’ve spent the last year helping clients navigate these “unprecedented times” and running the numbers. China has been cheaper even when you factor in massive tariffs. End of rant.

The Quotes, Compared:

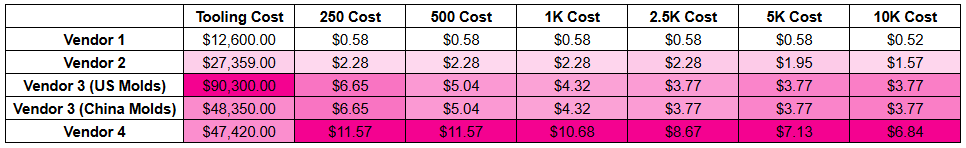

I tried to quote head to head as much as possible, requesting the same timelines and number of molds and lifetime specifications. I made a table to compare the total unit costs at various production quantities and added some fancy conditional formatting to make it easier to read:

The difference in pricing is pretty bonkers, but not super surprising. I was mostly shocked at the difference between Vendor 1 and Vendor 2, both of which are in China. I think this is due to markups mostly. Everyone’s gotta eat!

Vendor 3 was kind enough to provide quotes with molds made in China and shipped over, and molds made in the US. I think it’s fascinating the difference in the costs there. Note that the per unit price is still the same though, since the molding happens in the US.

Vendor 4 is outrageously expensive for each part. Again, only use them if you have no other options. Run away.

Effective Costs

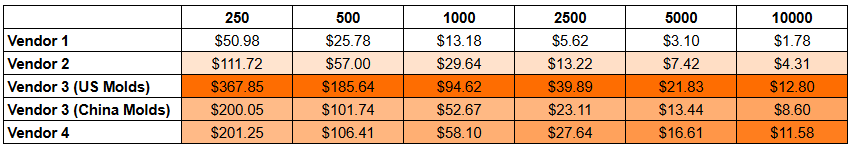

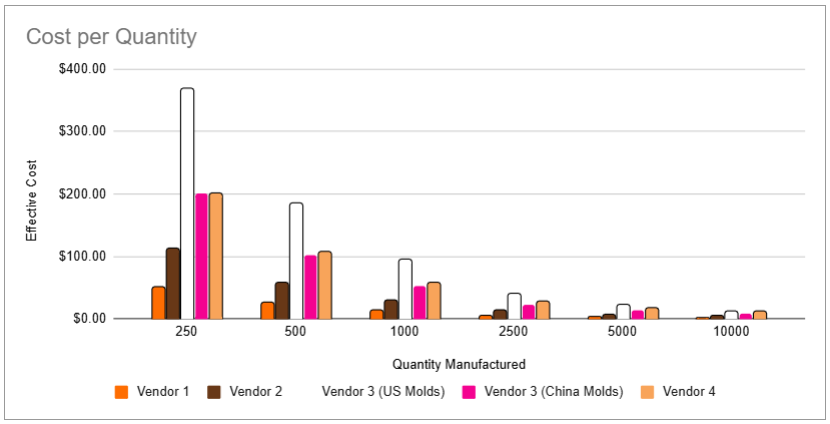

A better way to compare head to head is to look at the effective part cost.

A quick formula to use here is: Effective Part Cost = (Tooling Cost / Qty) + (Part Cost). The reason I like this formula is that it provides a single dollar value that scales with the amount you make.

Now we’re talking!

The increased tooling costs for US based molding really kicks up the effective part cost for Vendor 3. The increased part cost for Vendor 4 washes out with the low(er) tooling compared to Vendor 3, making them slightly more competitive.

The low part cost and tooling costs for Vendor 1 make them the obvious choice across the board here, however!

If you’re a more visual person, here you go:

Why such a large difference?

I alluded to it a bit above, but China is just a cheaper place to make things. China has been the go-to spot for manufacturing for decades, which means knowledge in tool making and the equipment has become almost commonplace. Entire towns are setup around these factories in China, and manufacturing has been subsidized by the Chinese government as part of a long term strategy for economic prospertiy.

The US has been outsourcing this knowledge, tooling, and support ecosystem for the same amount of time. This means that it’s harder to find good tool makers here, and to maintain the machinery and even train workers. The labor cost is also significantly higher in the US, which is excellent for workers rights but not so excellent in my very myopic analysis. We (used to) have higher standards for pollution as well, and making things while not destroying the planet as much is more expensive. There’s nothing political there - just straight facts.

So this leaves a burning question: when does it make sense to Injection Mold in the USA? For most products, my answer is “never”. However, there are some exceptions:

Super IP restricted projects. When knowledge MUST remain in the USA, you have no other choice. Think defense, military, telecom, etc. Or if you’re super super paranoid.

When “Made in the USA” can be applied as a marketing gimmick strategy that can demand a significantly higher retail price.

If the cost per unit isn’t important, and you’re trying to revitalize American Manufacturing. I salute you.

So, how much will it cost me to buy one?

I’ll save that for another post :)

There are many things to factor in:

tooling

manufacturing

assembly

packaging

shipping to US warehouse

tariffs

shipping to you

payment processing fees

my profit margin

website/marketing

And probably more than I included here. My aim is $15/unit at a few thousand units manufactured.

Sounds fair? I hope so!

What’s Next?

That’s a secret (for now). Let’s just say that things are taking an unexpected turn for the better :)

Ta ta!

💗 Sam