Floppy dropstoppers

Time truly flies these days. The holiday season is in full swing and I haven’t had as much time to dedicate to this project as I’d like. Things are moving and grooving still, but slow.

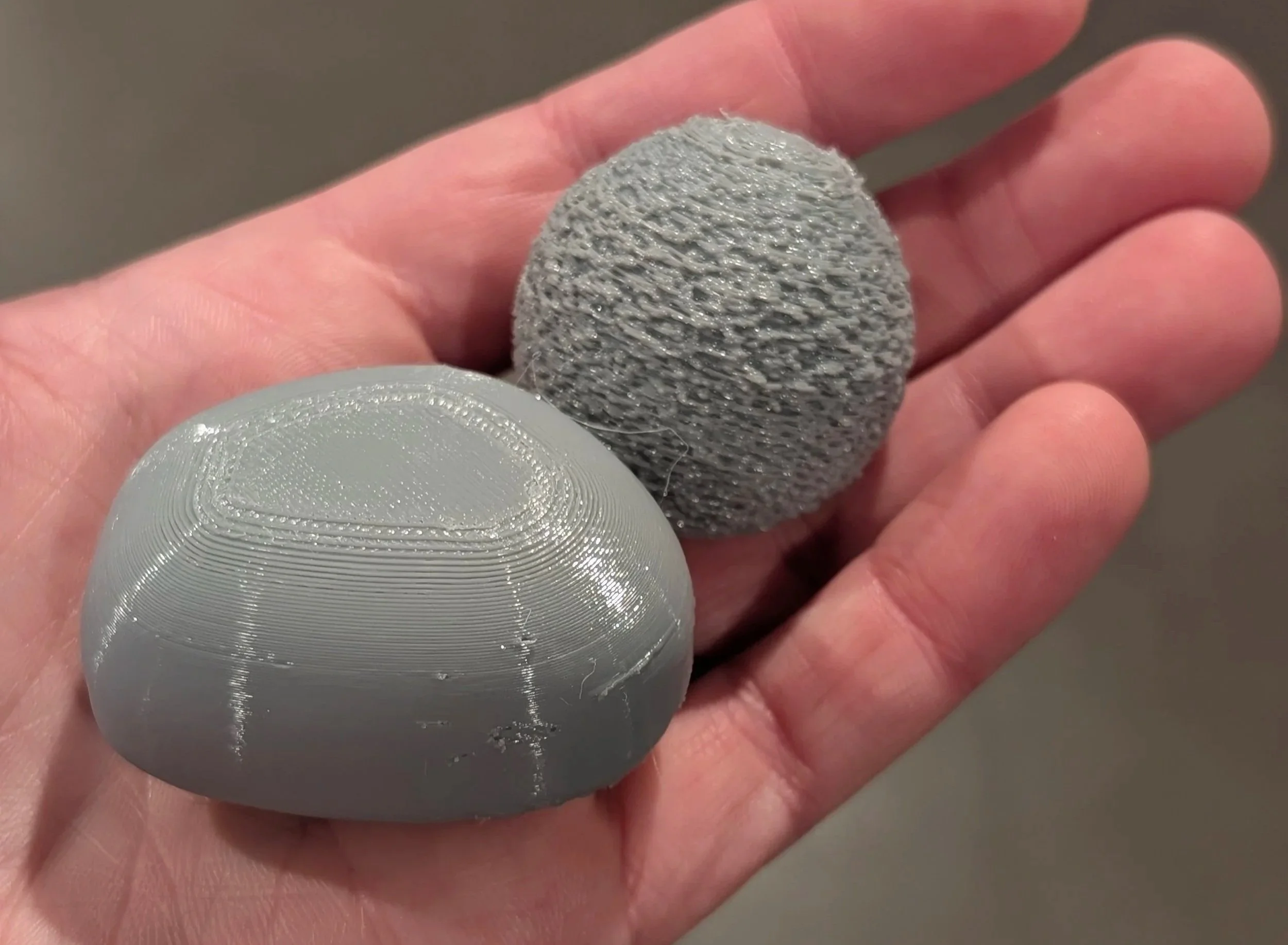

I have measured (and probably consumed) over 85 munchkins. I think this is a world record for data collection. In order to preserve my gut biome and cholesterol, I decided to 3D print a few munchkins that represent the various potential sizes, shapes and weights a donut hole-der may encounter in the real world. They’re printed in TPU, which is squishier than regular plastic materials. It feels like a donut that’s been left out for a few hours. It’s pretty good! I applied a slightly rough texture to the cake donuts to get as close as possible to the real deal. I don’t like how it feels.

Is it needed? No… but why are you even asking me that question? Read the room.

The Floppy Dropstopper:

As I alluded to a month (!) ago, I am still unhappy with how floppy the dispenser lever is. This is especially the case when you’ve got three cake donuts in the chamber (side note: this is a cool T shirt slogan). The weight of the donuts can override the lever mechanism and you’re at risk for a premature dispense or at least a peekaboo. It’s embarrassing. God forbid anyone jog with one of these!

Frankly, I know I can do better here, so I started running some experiments. This is a common part of the prototype process - get pretty far and lock down most stuff, then refine a few key variables.

If you recall from my previous overview, there are a handful of dimensions I can adjust here to change how the hole-der performs. My thinking is that these four areas need some refinement:

1: How high up the pivot point is in relation to the donut (dimension A).

- Increasing this distance reduces how much you need to depress the lever to drop a donut.

2: How much of the donut is held by the lever (dimension B).

- Capturing more means you need to press in more to release a donut.

3: The thickness of the dropstopper spring arm (dimension C).

- A thicker spring arm means there is more force needed to press the lever in.

4: The length of the lever which pushes against the dropstopper (dimension E).

- Increasing this length increases the spring force and also how much of the next donut is held in place from falling.

I ran a quick test and glued a 0.5mm sheet of plastic on top of the dropstopper spring arm. The lever was a bit harder to press in, but held donuts much better. I still knew there was room for improvement, however.

I spun out 3 variations of my 3D model to print and evaluate. Each model changed one dimension listed above. I then tested each model against my existing device and whittled down which items to dial in further. The result is a device with a thicker dropstopper spring arm, holding more of the donut, and with a slightly smaller lever arm.

I think I’m there. I feel good about this one! I think it’s even possible to do light exercises with it on, but I’ll need someone else to validate that one for me. That’s why I need you!

Let’s beta test this sh*t.

Now that everything is dialed in, I want to get these in the hands of real folks who eat real donuts! If you’re a real folk and you eat real donuts - hit me up!

I’ll be printing off a bakers dozen (that’s 13) of these bad larry’s to hand out for testing, absolutely free. Be the envy of your friends, confuse the staff at your local Dunkin’, and please film some social media content for me. In exchange, you get to join the ranks of a very select few donut hole-der-holders.

Want in? Shoot me an email and tell me why you’re the right person for the job. I’ll answer each and every one of you (all 4).

What’s next?

I don’t know. I still think it’s funny. It still makes people laugh, and I get asked about it enough that I still think it should exist in the real world. It doesn’t feel like big donut wanna give me a pontoon boat though. Maybe I’ll have to take this into my own hands. Stay tuned and please share this with anyone you know who thinks you’re kinda weird already.

💗 Sam