Refinement time

Hi! I’m doing great, thanks. You?

Let’s jump right into what’s been going down since we last touched base. I’ve been hard at work refining the dropstopper mechanism to make sure it reliably dispenses all types of donuts. It turns out, there are a lot of variables at play here. Let's’ check out a few key ones below:

| Variable | Description | What it changes |

|---|---|---|

| A | Pivot point location | How far back you need to press the lever to dispense a donut How far the drop stopper sticks out |

| B | Amount of donut held | How far back you need to press the lever to dispense a donut How far the drop stopper sticks out How well the next donut is prevented from falling out |

| C | Thickness of Dropstopper | How much force is required to push the lever back How well the next donut is prevented from falling out |

| D | Overlap of Dropstopper | How far the drop stopper sticks out |

| E | Length of pivot arm | How far the drop stopper sticks out How much force is required to push the lever back |

| F | Length of Dropstopper | How far the drop stopper sticks out How much force is required to push the lever back |

| G | Diameter of Donut | How far back you need to press the lever to dispense a donut How many different donut shapes can be held |

As you can see, there is a ton of overlap here. Making one tweak to the geometry can have accidental impacts on other features too. In one attempt to make the device a bit more compact, I accidentally made it much harder to dispense donuts since the dropstopper became too short. Another time I made the dropstopper too long and started crushing donuts.

Finding the right balance of these dimensions has taken a ton of time and I think I may have finally cracked the code! No- I won’t share that code with you, but nice try, Tim Hortons!

This is all to say that getting everything to work just right has taken many many many iterations - and many many many more donuts. I’ve measured 49 donuts now and have great ambitions to streamline this process soon with a custom munchkin measurement device. I also think I have the record for most munchkins measured now - so that’s cool.

The pillowly loaf conundrum:

Thanks to my friend Becca, I learned that “pillowy loafs” are yeasted donuts and “fried balls” are cake donuts. The yeast makes the donut far lighter and fluffier which makes them much much harder to dispense. They are less consistent, more prone to jamming, and like to slip through the dispenser. If I wanted, I could ignore yeasted donuts altogether and make a very reliable cake donut dispenser and call it a day. Unfortunately, I need to make this device work with all types of donuts. You can’t ignore glazed and jelly munchkins altogether, right?

The latest design:

So, more tweaking and refining was required to support the most donuts possible. And here we are! The latest design looks a lot different than the previous design for a few good reasons!

Change 1: Design for injection molding.

The major difference between this design and the previous ones is that it has been created with mass manufacturing in mind.

When I’m not optimizing a munchkin dispenser, I mainly am designing products for injection molding for clients. I’m pretty good at it too!

There are many rules you must follow (and some you can break) to make a part that can be successfully injection molded. I’m applying all of my experience here to ensure this product can be reliably mass manufactured but also look and work well too.

It’s still a work in progress🙂

Change 2: Circular to oval cross section

First off, I’ve adjusted the inside shape from a cylinder into an oval, which allows the pillowy donuts to orient themselves well and stop binding. The dimensions of this oval are based on my measurements of many many munchkins and a bit of statistics. I am aiming for compatibility with 75% or more of all donuts.

Sprinkle covered donuts are not going to work here, and I’m fine with that.

Change 3: increased donut retention

Some yeasted donuts were slipping past the trigger and out of the holder. To rectify this, I’m holding more of the donut, which means you need to press the lever in more. The shape of the lever has been tweaked to make it easier to press all the way in without jamming against your leg. The butterfly effect of changing things is endless!

Change 4: Peekaboo window

I’ve also added a peekaboo window to allow for a quick glance at what donut is on deck and to see if we need a refill. The front face of the dispenser is prime real estate for a company logo too.

Change 5: Snap lid

The last major change is the new snap lid. This new lid is easy to open and close one handed, remains attached to the device when the lid is open, and adds a dope pop of color. Shout out to the wickedly talented Andrew Brase for helping me refine the overall form of the dispenser and for the inspiration here!

Getting serious:

As you know, I suck at social media. I’m working on it, but I still suck at it. Instead, I’ve been chatting with folks who have connections in advertising, influencer networks, and social media marketing to better understand how to get this across the right person’s phone screen.

There may be a world in which I can do this for other brands too (If you’re one of those brands - hit me up!).

I was also recently interviewed by Jay Sugarman’s Innovation Showcase series on newTV about my experience and approach on this project, which was super fun. I’ll share that recording when it’s live, and you’ll see why I don’t do a lot of public speaking.

I’m immensely excited to share that I have started the patent process with our friends over at Keeley DeAngelo and I’ll be documenting the process of obtaining a Design and Provisional Patent soon. (Apparently it’s not a great idea to just share ideas like this on the internet since bad actors may swoop in and steal your thunder.)

Lastly, I’ll leave you with this absolute banger of a song created by my friend Jackson using AI. I can’t get it out of my head.

Next Steps:

I feel like I’m nearly there! My todo list is getting shorter and shorter

Measure more munchkins (MMM)

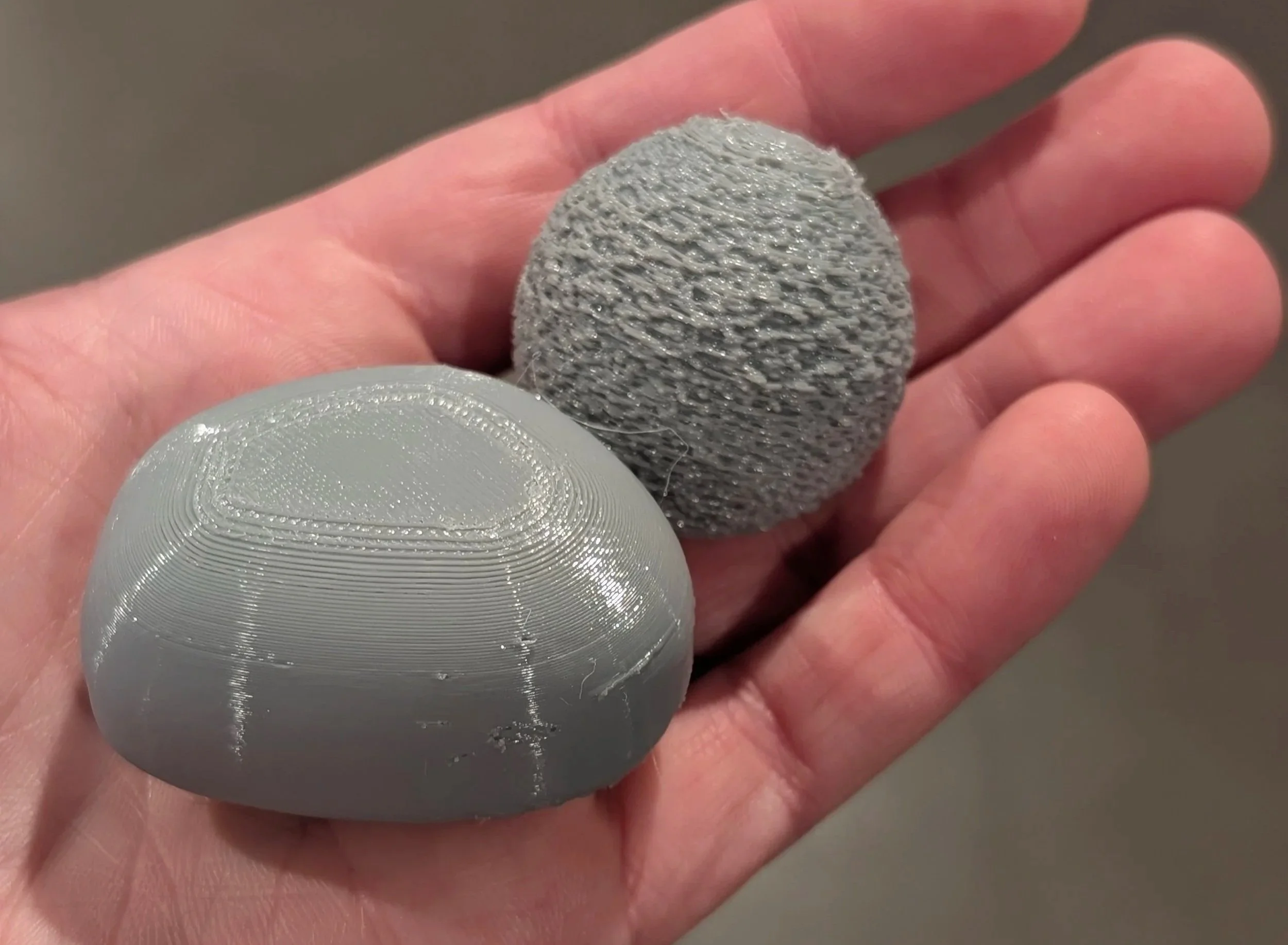

Prototype, iterate, and test!

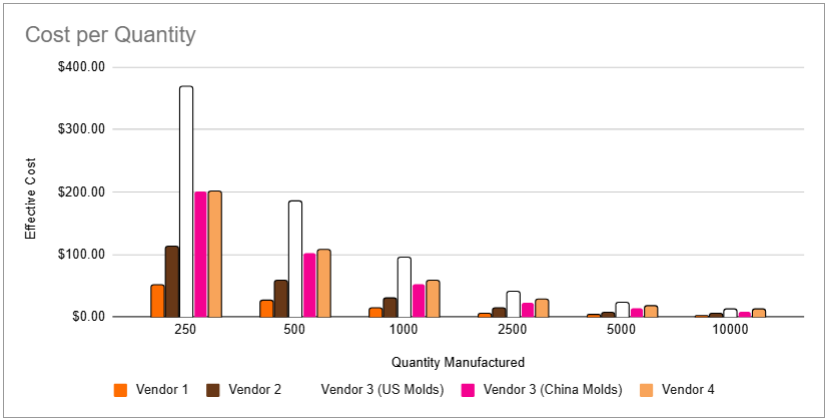

Obtain quotes for manufacturing

???

Pontoon boat.

As always, please share this with anyone you think would chortle or even strongly exhale out of their nose at this. If you or anyone you love is high up at Dunkin’ you know what to do.

Wanna read more stuff?